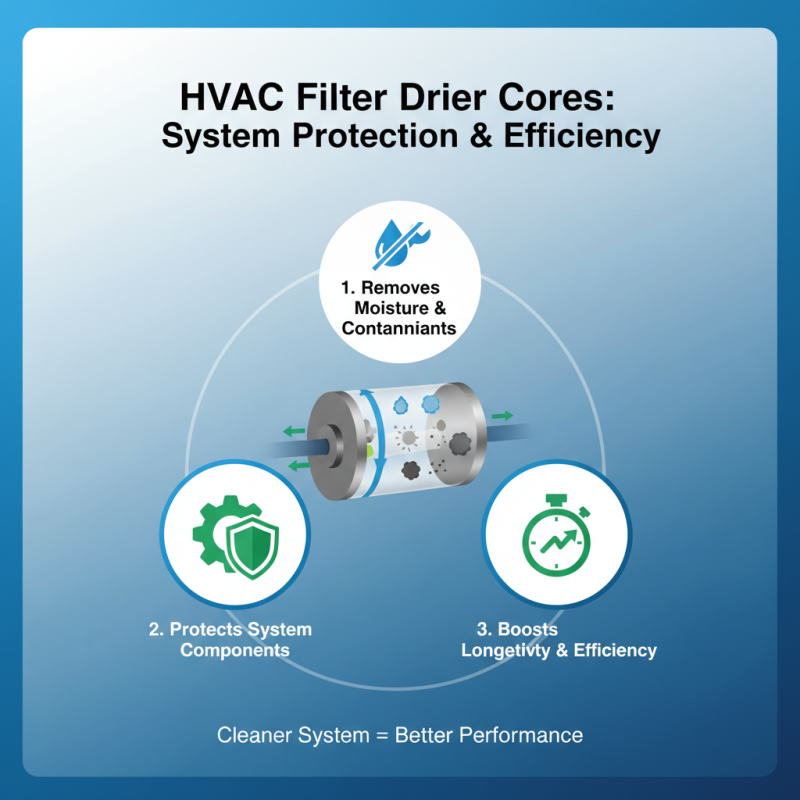

In the world of HVAC systems, the "Filter Drier Core" plays a vital role. This component acts as a guardian for your system, ensuring efficient operation. Its benefits extend beyond simple filtration; they contribute to the longevity and reliability of HVAC systems.

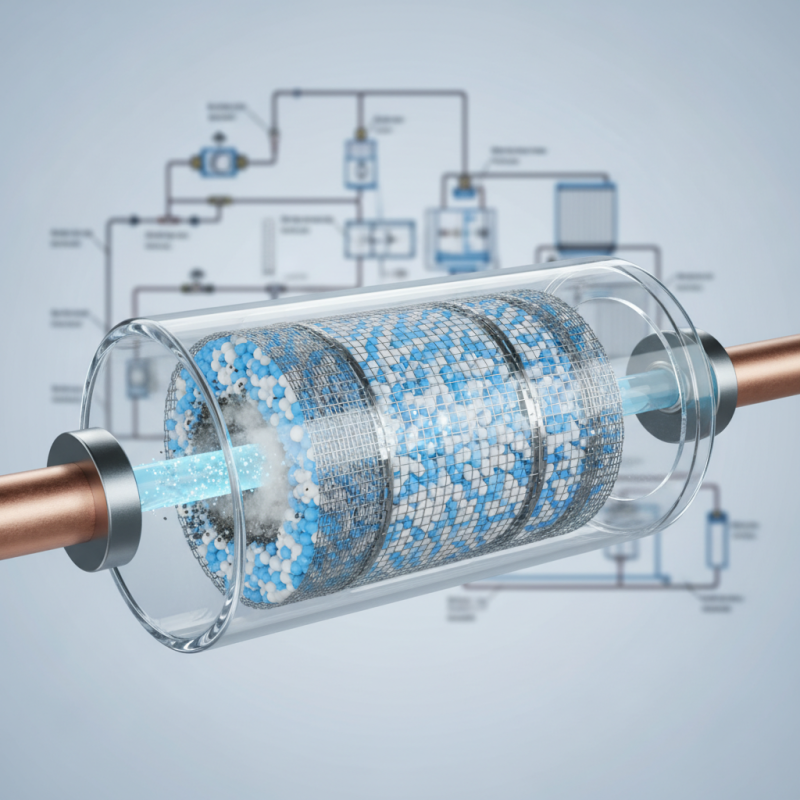

One key advantage is moisture removal. Excess moisture can damage components. The Filter Drier Core absorbs this moisture, preventing corrosion and other issues. Additionally, it filters out contaminants, ensuring only clean refrigerant circulates through the system. This leads to improved performance levels and energy efficiency.

However, not all systems utilize the Filter Drier Core effectively. Some neglect its importance, leading to potential failures. Maintenance practices often overlook this crucial component. The consequences can be significant, affecting not only comfort but also operational costs. Understanding the benefits of the Filter Drier Core is essential in maximizing HVAC systems' performance.

Filter drier cores play a crucial role in HVAC systems. They help to remove moisture and contaminants from refrigerants. This process is vital. Moisture in the system can lead to corrosion and damage. According to industry reports, over 50% of HVAC failures are linked to moisture issues.

Incorporating a filter drier core can enhance system efficiency significantly. Studies show that systems using filter driers operate 20% more efficiently compared to those without. This increase can save energy costs over time. However, not all filter drier cores are the same. Some may clog too quickly, leading to reduced airflow. Regular checks are essential to ensure optimal performance.

Additionally, installing the wrong size filter drier may cause issues. Oversized or undersized units can disrupt the entire system. A common mistake is neglecting to replace filter driers at regular intervals. Doing so can jeopardize the reliability of the HVAC system. Keeping track of these factors is key to smooth operation.

Filter drier cores play a vital role in HVAC systems. They effectively remove moisture, dirt, and contaminants from refrigerants. By doing this, they protect the entire system. This protection enhances the longevity and efficiency of the components. A clean environment inside the system means better performance and fewer breakdowns.

Effective filters support smooth operation during heating and cooling processes. They prevent blockages that could lead to increased energy consumption. Besides, maintaining a balanced system reduces the workload on the compressor. This decline in strain can extend the lifespan of your HVAC unit. One often overlooked aspect is the need for regular replacements. Neglecting this can lead to decreased effectiveness over time.

Utilizing filter drier cores helps in maintaining optimal performance. They contribute to cleaner, healthier air indoors. In some cases, systems can suffer from reduced airflow if the filters are not monitored. Users may experience unexpected humidity levels, signaling a need for change. Regular checks and replacements are crucial for consistent comfort. Ultimately, they are a small investment for increased efficiency and reliability.

In HVAC systems, filter drier cores play a vital role in enhancing efficiency and longevity. These components remove moisture from refrigerants. They also trap contaminants that could harm other system parts. By ensuring clean refrigerant flow, they help maintain optimal performance. Systems equipped with effective filter drier cores usually show improved energy savings. This efficiency translates into lower operational costs.

Regular maintenance of filter drier cores is crucial. Clogged or damaged cores can lead to inefficiencies. Replace them when you notice a drop in system performance. Monitoring performance can prevent larger issues down the road. Keep an eye out for unusual noises or fluctuating temperatures.

Tip: Always use the correct type of filter drier core for your system. Compatibility matters. Installing the wrong type can cause problems. Consult professionals if you're unsure.

Additionally, be aware that filter drier cores have a lifespan. They do not last forever. Over time, they absorb moisture until saturated. This saturation can inhibit function. Replace them as recommended by your system’s guidelines. Ignoring this can lead to costly repairs.

Filter drier cores play a crucial role in HVAC systems. They are essential for preventing contaminant damage. These components filter out impurities such as moisture and debris from refrigerants. Keeping the refrigerant clean helps maintain system efficiency. A clean system means better energy savings and longer equipment life.

Regular maintenance is vital. Always check the filter drier core during routine inspections. If you notice signs of wear or clogging, it's time for replacement. A faulty core can lead to bigger issues. It can cause compressor failure and costly repairs down the line.

Tip: Keep an eye on the refrigerant charge. Low levels can stress the filter drier core. Also, consider using a sight glass. It can help monitor the moisture level in the system. Remember, neglecting these checks may lead to system inefficiencies. So, don't overlook the importance of a clean filter drier core.

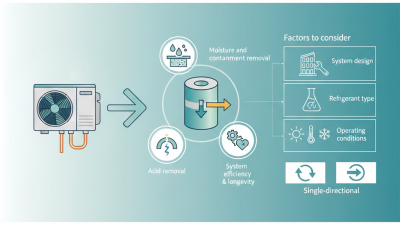

Choosing the right filter drier core is crucial for efficient HVAC system performance. Filter drier cores help remove moisture, contaminants, and acids from refrigerants. This process extends equipment life, ensuring reliable operation. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers, proper system moisture levels can increase efficiency by up to 20%.

When selecting a filter drier, consider system type, size, and refrigerant. Not all cores suit every application. For instance, an oversized filter drier can lead to pressure drops and reduced efficiency. It's vital to match the core specifications with the HVAC system requirements. Keep in mind that improper selection can cause operational issues.

Tip: Always check compatibility with refrigerants used in your system. Investing time in this step can save money in the long run.

Additionally, verify the moisture absorption capacity of the filter drier. Some may not handle high moisture levels effectively. An underperforming filter drier might lead to refrigerant breakdown, which is a costly mistake. Aim for units with clear specifications and data to guide your choice.