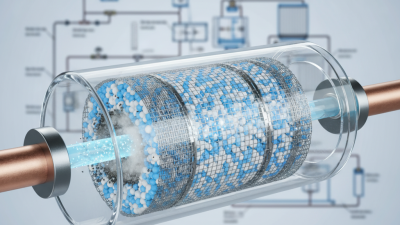

In the realm of HVAC systems, the Filter Drier plays a crucial role. It ensures the longevity and efficiency of the system. A well-functioning filter drier prevents contaminants from circulating through the refrigerant. This reduces wear and tear on crucial components.

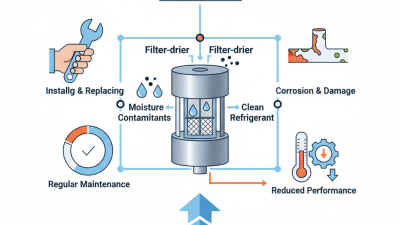

Many neglect the importance of this device. They may overlook regular maintenance, leading to larger issues. A dirty or damaged filter drier can cause refrigerant leaks and inefficiency. This oversight can lead to costly repairs down the line.

Understanding its importance can help users better maintain their HVAC systems. Regular checks and timely replacements are vital for optimal performance. The filter drier is an unsung hero in HVAC, and its role is often underestimated. Proper attention to this component can make a significant difference in system reliability.

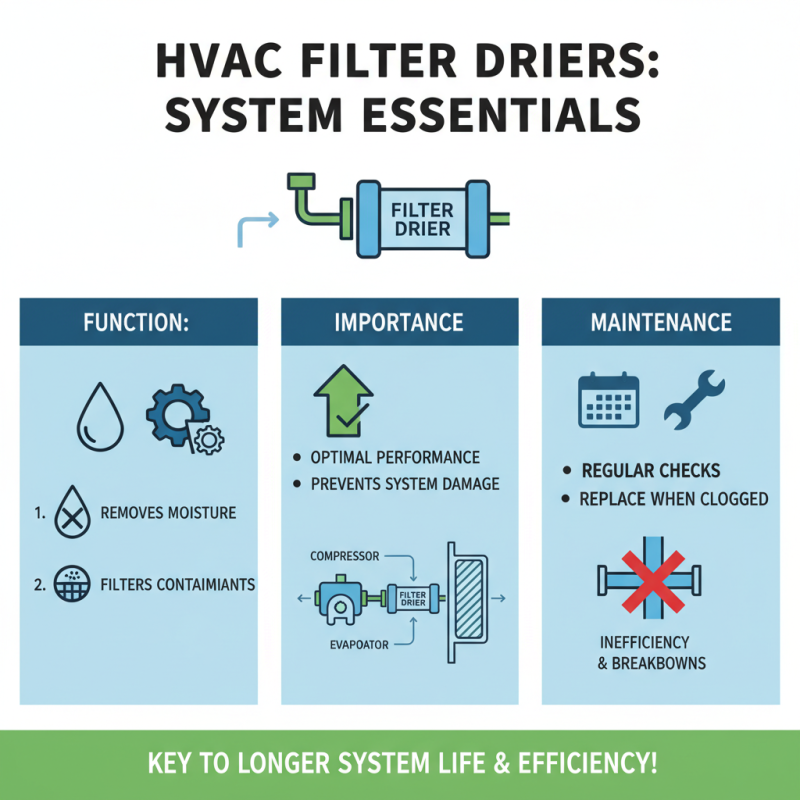

Filter driers play a crucial role in HVAC systems. They help maintain the overall efficiency of cooling and heating processes. According to a report from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), nearly 80% of HVAC system failures are due to moisture and contaminants. These issues can lead to significant operational costs and downtime.

A filter drier removes moisture and debris from the refrigerant. This process ensures smoother operation and prolongs the lifespan of HVAC components. Neglecting this aspect can result in clogged systems. Research shows that systems without proper filtration can lose up to 15% efficiency within the first year. That's a staggering waste of energy and resources.

Monitoring a filter drier's condition is essential. Often, filters become saturated and fail to serve their purpose. Regular checks can prevent costly repairs. However, many technicians overlook this preventative measure during routine maintenance. This lack of diligence can result in reduced efficiency and increased wear on compressors and evaporators. There’s a clear need for greater awareness and proactive measures in this area.

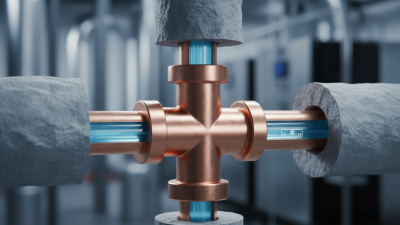

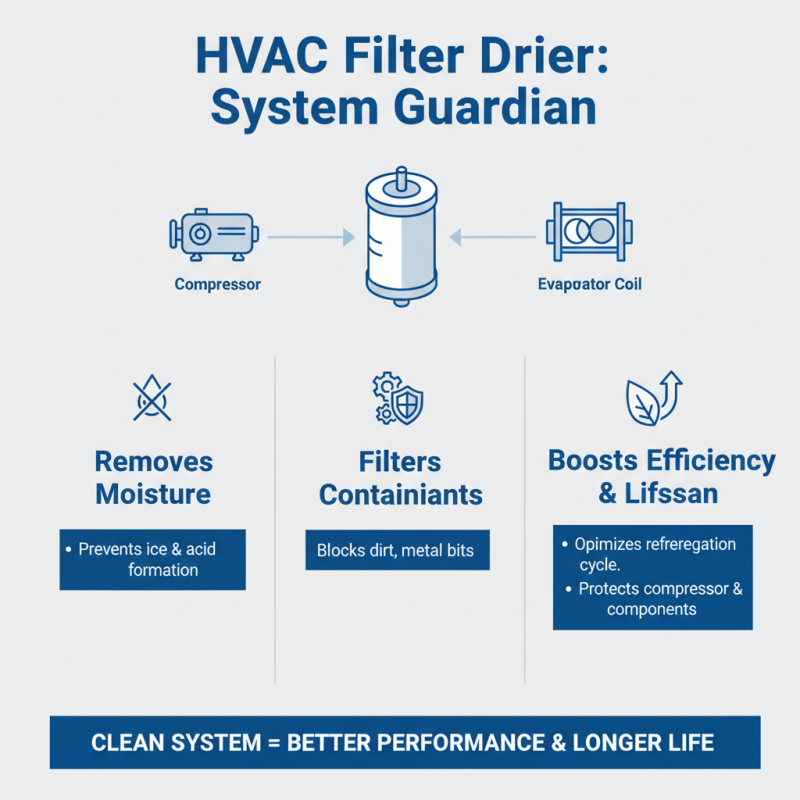

The filter drier plays a crucial role in HVAC systems. It helps maintain the efficiency of refrigeration cycles. By removing moisture and contaminants, it protects the compressor and other components. A clean system operates better and lasts longer.

In the refrigeration cycle, refrigerant must remain uncontaminated. When moisture enters, it can cause corrosion and system failure. The filter drier absorbs excess moisture and filters particulates. This process is vital to preventing damage. Regular maintenance checks are essential. Without them, the system can fail unexpectedly.

**Tip:** Always watch for signs of refrigerant leaks. They can indicate filter drier issues.

Another point to consider is the filter drier's lifespan. It does not last forever. Filters can become saturated, rendering them ineffective. Regularly replacing the filter drier will keep the system running smoothly.

**Tip:** Schedule annual inspections for your HVAC system. This is a simple way to prolong its life.

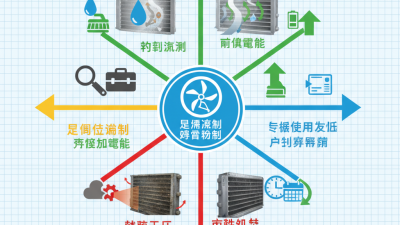

Moisture and contaminants can significantly impact the efficiency of HVAC systems. According to industry reports, excessive moisture can reduce HVAC efficiency by up to 25%. This reduction leads to increased energy consumption and higher utility bills. Moisture in the refrigerant system often leads to corrosion, which can weaken system components.

Contaminants like dirt and dust can also have a detrimental effect. They can clog filters and coils, resulting in restricted airflow. A study found that clogged filters could increase the system's energy usage by approximately 15%. Regular maintenance is crucial to keep HVAC systems running efficiently. Unfortunately, many systems are neglected, leading to potential problems down the line.

A filter drier plays a vital role in maintaining the integrity of the HVAC system. It absorbs moisture and filters out contaminants before they can cause harm. Without a filter drier, the risk of freeze-ups and compressor failure increases significantly. In some cases, a failure to address moisture has led to complete system breakdowns, costing thousands in repairs. Regular inspection and replacement of filter driers can prevent these costly issues.

Filter driers play a crucial role in HVAC systems. They help remove moisture and contaminants from refrigerants. Regular maintenance is essential for optimal performance. Without proper care, driers can become clogged, leading to system inefficiencies.

One key tip for maintaining filter driers is to check them frequently. A visual inspection may reveal signs of wear or buildup. Replace any drier that shows signs of damage. This simple step can prevent larger issues later. Avoid delays in replacement, as this can affect overall system health.

Another important consideration is proper installation. Ensuring the drier is installed correctly can extend its life. Misplacement or improper connections can lead to leaks. Evaluating installation periodically is a wise choice. Keep an eye out for any unusual noises or changes in performance. Addressing these signs early can save time and money in the long run.

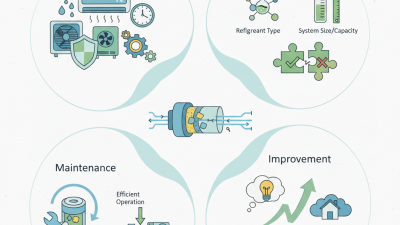

Choosing the right filter drier for HVAC systems is crucial. Different applications demand different specifications. For example, a residential air conditioning system may require a standard filter drier, while commercial setups might need a specialized model. Understanding the unique requirements of each system helps in making the right choice.

Material compatibility is vital. Some driers perform better with certain refrigerants. If the match is not right, the filter drier could fail. This results in inefficiencies and potential system damage. Regular maintenance checks can reveal if the current drier is adequate. An overlooked aspect can lead to unexpected issues.

In some instances, size and shape also matter. A poorly fitted drier may restrict airflow. This can increase energy consumption and reduce system efficiency. It's essential to consult with professionals to ensure proper sizing. A wrong decision here can have long-term consequences for system performance. Each application deserves careful thought and consideration.

| Dimension | Importance | Application | Recommended Type |

|---|---|---|---|

| Moisture Removal | Prevents refrigerant degradation | Residential AC systems | Molecular sieve filter drier |

| Debris Filtration | Protects compressor and components | Commercial refrigeration units | Core type filter drier |

| Acid Neutralization | Prevents system corrosion | Chillers | Heat activated filter drier |

| System Efficiency | Enhances overall performance | Heat pumps | Liquid line filter drier |