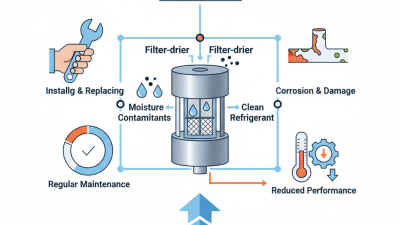

A Filter Dryer is an essential piece of equipment in many industrial processes. It efficiently separates solids from liquids while removing moisture. Filtration is crucial in achieving a high-quality final product. The Filter Dryer combines these two functions.

In operation, the Filter Dryer utilizes a membrane or cloth to capture solid particles. These particles are retained as the liquid is removed. The process is often used in pharmaceuticals and chemical industries. It allows for clean and dry solid materials. However, achieving optimal performance can be challenging. Factors like the type of material and moisture content influence efficiency.

Understanding how a Filter Dryer works is key to maximizing its benefits. Users must carefully consider their specific applications. The right design and operation can lead to better results. Yet, there is always room for improvement. Continuous evaluation of the process can help identify areas for enhancement.

A filter dryer is a crucial piece of equipment in various industries, particularly in pharmaceuticals and chemicals. It combines filtration and drying processes. This dual action ensures that solid particles are removed while keeping the moisture content low. The complex design allows it to handle both solid and liquid phases effectively.

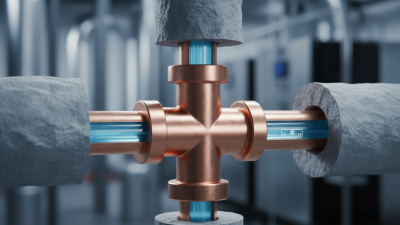

The filter dryer operates by first receiving a slurry or suspension. It then separates the liquid from the solid using a filter medium. Gentle pressure follows to remove excess moisture. The design can vary based on specific applications but typically involves a robust vessel that can withstand various temperatures and pressures.

Tips: When using a filter dryer, maintain the right temperature. High temperatures can lead to product degradation. Ensure proper maintenance of the filter medium. Clogged filters can hinder efficiency and increase processing time.

Once the filtration is complete, the drying phase begins. It can be challenging to achieve uniform drying throughout the product. Inconsistencies often occur due to varying particle sizes and shapes. Checking the moisture levels periodically during the process is essential. It helps in mitigating over-drying or under-drying issues, which can affect the final product quality.

This bar chart illustrates various performance metrics associated with filter dryers. The data showcases efficiency percentage, energy consumption, cost, maintenance frequency, and waste generation, providing insight into how filter dryers operate in industrial applications.

A filter dryer is a crucial piece of equipment in various industrial processes. It combines filtration and drying to remove moisture from solid materials. Understanding its components can highlight its importance in manufacturing and processing sectors.

The main components of a filter dryer include a filtration unit, a drying chamber, and a discharge system. The filtration unit often employs a medium that captures solids while allowing liquids to pass through. Data from industry reports indicate that effective filtration can remove up to 99% of particulate contaminants. The drying chamber follows, where heat is applied. This step is essential for achieving low moisture content. It is important to note that improper drying can lead to clumping or microbial growth, which can compromise the quality of the final product.

The discharge system typically ensures that processed materials are removed efficiently. Many systems utilize pneumatic or mechanical means for this purpose. Occasionally, this system can encounter blockages, which require maintenance. Such issues should not be overlooked, as they can delay production timelines. Industry data shows that regular inspections can reduce downtime by 30%. Understanding these components can enable better management of filter dryer systems in any operation.

Filter dryers are designed to effectively remove moisture from various substances while ensuring product purity. Their operation is a fascinating process that involves several key stages. Initially, the material is fed into the dryer, where it is mixed with a heating medium. This medium can be either steam or hot air, which raises the temperature, aiding in the evaporation of moisture.

During the drying phase, a filter element plays a crucial role. It separates the solid particles from the vaporized moisture. Data indicates that filter dryers can achieve moisture content levels as low as 0.5% in certain applications, which is critical for industries like pharmaceuticals or food processing. However, achieving such low moisture levels can sometimes lead to over-drying. This may negatively affect product quality, highlighting the need for constant monitoring.

As the process concludes, the solid residues are separated from the vapor. The efficiency of this system is noteworthy; reports show an average energy consumption of 1.5 kWh per kilogram of product dried. Nonetheless, achieving optimal energy use remains a challenge for many operations. Balancing efficiency with product integrity often requires adjustments and careful assessment.

Filter dryers play a vital role across various industries by efficiently separating solids from liquids while also drying the solids. In the pharmaceutical sector, filter dryers are used for producing active pharmaceutical ingredients (APIs). Their ability to manage temperature-sensitive materials makes them invaluable. Dust-free operations ensure worker safety and compliance with stringent regulations.

In food processing, these dryers remove moisture from products like powdery spices or instant soups. This process maintains flavor and quality, avoiding spoilage. Their versatility helps in maintaining product consistency. When tackling different types of materials, adjusting parameters is key. Finding the right balance can be challenging.

Tip: Always conduct a thorough assessment of material properties before selecting a filter dryer. This can save time and resources.

In the chemical industry, filter dryers facilitate the drying of catalysts and intermediates. This step is crucial for reducing production costs. However, monitoring performance and preventing clogs can be an ongoing challenge. Regular maintenance plans should be developed.

Tip: Implement routine checks on your filter dryer’s components. Small issues can lead to significant downtime later.

| Industry | Application | Benefits | Typical Materials Processed |

|---|---|---|---|

| Pharmaceutical | Active Pharmaceutical Ingredients (APIs) | High purity, precision filtering, and drying | Powders, crystals |

| Food & Beverage | Concentration of juices and flavor extracts | Food safety, extended shelf life | Liquids, slurries |

| Chemical | Drying of chemicals and catalysts | Efficiency, reduced contamination risks | Granules, powders |

| Plastics | Drying of plastic polymers | Improved product quality, moisture control | Polymer resins |

| Mining & Minerals | Separation and drying of mineral slurries | Enhanced recovery, reduced waste | Mineral concentrates |

Filter dryers offer significant advantages in material separation processes. They combine filtration and drying into one efficient unit. This dual function saves time and resources. Removing moisture while separating solids ensures high product quality. The process is often more streamlined than using separate systems.

Using filter dryers can reduce operational costs. They minimize the need for extra equipment and labor, which lowers overhead. Additionally, filter dryers can increase yield. They optimize the extraction of useful materials while minimizing waste.

However, there are considerations to keep in mind. Not every material is suitable for filter drying. Some might require specialized handling or processing conditions. This can lead to potential inefficiencies. Regular maintenance is vital to avoid performance issues. Balancing the benefits with these challenges is crucial for effective use.