In the complex world of HVAC systems, ensuring optimal performance and longevity hinges on several critical components, one of which is the Filter Drier Core. This essential element plays a significant role in maintaining the efficiency of refrigeration and air conditioning systems by removing moisture and contaminants from the refrigerant. According to industry expert Dr. Michael Johnson, a leading figure in HVAC technology, "the Filter Drier Core is the unsung hero of HVAC systems, safeguarding them from potential damage caused by moisture and debris."

The importance of the Filter Drier Core cannot be overstated, as it directly impacts system reliability and energy efficiency. By filtering out impurities and absorbing moisture, it prevents corrosive reactions within the system that can lead to costly repairs and decreased performance. As HVAC systems continue to evolve, understanding the role of the Filter Drier Core and its maintenance becomes increasingly crucial for professionals in the field, ensuring that systems operate smoothly and efficiently for years to come.

In summary, the Filter Drier Core is a pivotal component that ensures not only the effectiveness of HVAC systems but also their longevity. With insights from experts like Dr. Johnson, the significance of this core element becomes clear: it is fundamental to the health of HVAC systems across various applications.

In HVAC systems, the filter drier core serves a crucial role in maintaining optimal performance and longevity. This component is designed to remove moisture and impurities from the refrigerant, protecting the system from potential damage. Moisture can lead to corrosion, rust, and the formation of acids, all of which can severely impact the efficiency and reliability of the HVAC system. The filter drier core not only ensures that the refrigerant remains clean but also plays a vital part in preventing compressor failures and other costly repairs.

When selecting a filter drier core for an HVAC system, it's essential to consider factors such as the refrigerant type and system capacity. Proper installation and maintenance are equally important to maximize its effectiveness. Regular checks can help identify any blockages or saturation of the core, which can impair its functionality.

Tips: Always consult with HVAC professionals for proper installation techniques and maintenance schedules. Additionally, when replacing the filter drier core, ensure that the entire HVAC system has been thoroughly evacuated to prevent introducing contaminants. Keeping a proactive approach can significantly enhance system performance and durability.

| Feature | Description | Importance in HVAC Systems |

|---|---|---|

| Moisture Removal | Removes moisture from the refrigerant. | Prevents corrosion and damage to the compressor and other components. |

| Contaminant Filtration | Filters out dirt, debris, and acids. | Protects the system’s efficiency and longevity. |

| Refrigerant Flow | Allows unrestricted flow of refrigerant. | Ensures optimal cooling performance. |

| Size and Design | Compact design to fit various system sizes. | Facilitates easy installation and maintenance. |

| Replacement Frequency | Subject to wear and needs periodic replacement. | Maintaining optimal performance and effectiveness of the HVAC system. |

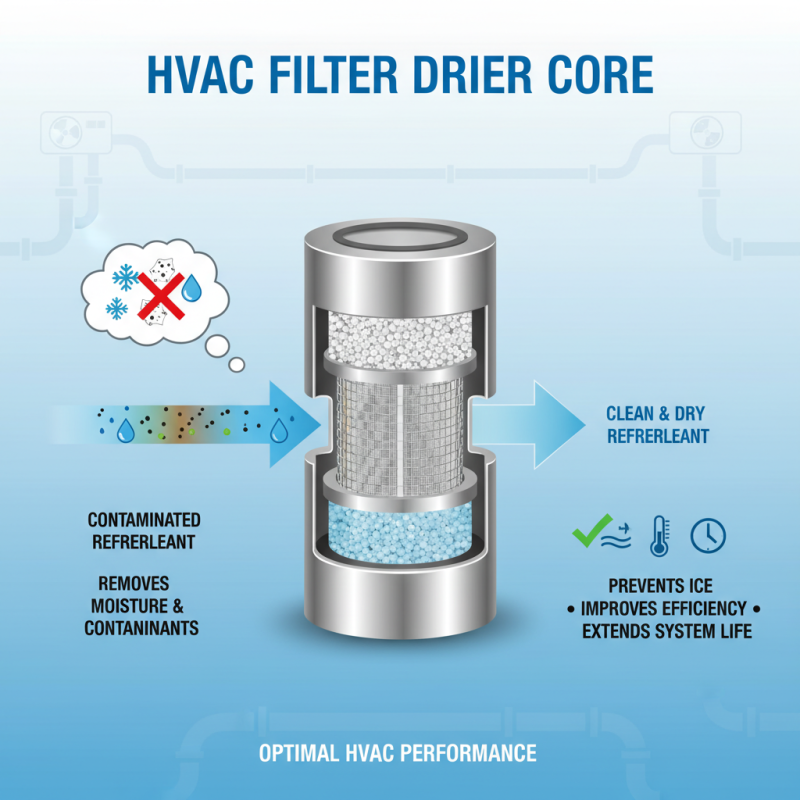

Filter drier cores play a critical role in the functionality of refrigeration cycles within HVAC systems. These components function primarily to remove moisture and contaminants from the refrigerant. In a refrigeration cycle, moisture can lead to ice formation, which can obstruct the flow of refrigerant and reduce system efficiency. By effectively filtering out contaminants and moisture, filter drier cores help maintain optimal operating conditions, therefore enhancing the reliability and longevity of the HVAC system.

Additionally, filter driers provide essential qualities such as adsorption and filtration. The core contains desiccant materials that absorb moisture and trap particles, preventing them from circulating through the system. This not only protects the compressor and other critical components from damage but also ensures a cleaner, more efficient refrigeration cycle. Without a functioning filter drier core, systems are at risk of reduced efficiency, increased energy consumption, and potentially costly repairs due to failures resulting from contamination. Thus, the importance of filter drier cores in maintaining the integrity of HVAC systems cannot be overstated.

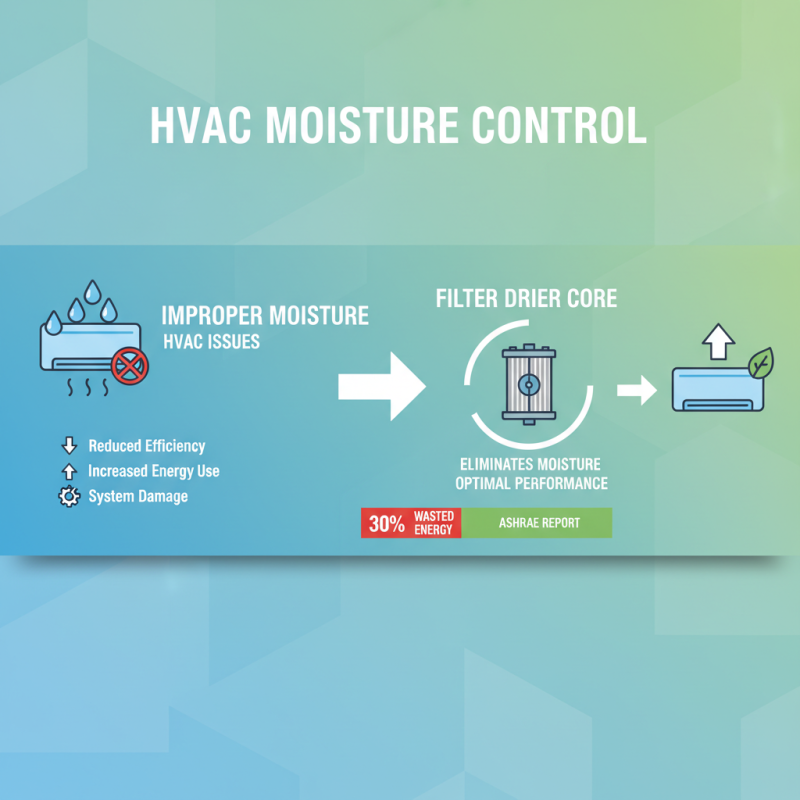

Moisture control is a critical aspect of HVAC system performance, as excessive moisture can lead to a range of issues including reduced efficiency, increased energy consumption, and potential damage to system components. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), approximately 30% of energy usage in commercial buildings is wasted due to improper moisture management. This highlights the essential need for a filter drier core, which serves to eliminate moisture from the refrigerant, ensuring that HVAC systems operate at optimal performance levels.

The presence of moisture in the refrigerant can lead to the formation of acids and sludge, which can cause corrosion and wear on critical components like compressors and expansion valves. Studies indicate that even small amounts of moisture can reduce the lifespan of HVAC equipment by up to 50%. By incorporating a filter drier core, systems can effectively remove moisture and contaminants, thereby enhancing reliability and longevity. Moreover, maintaining proper moisture levels not only extends equipment life but also improves overall system efficiency, facilitating lower energy bills and a reduced carbon footprint for buildings over time.

A malfunctioning filter drier core can lead to several critical issues within HVAC systems, impacting efficiency and potentially causing costly repairs. One common problem is the accumulation of moisture in the refrigerant system. According to industry reports, moisture levels exceeding just 0.1% in refrigerants can lead to ice formation, which blocks filters and restrictions in pipelines, ultimately reducing the system’s performance and increasing energy consumption by up to 20%. This not only challenges the longevity of components but also strains the compressor, which relies on consistent operational conditions to perform efficiently.

Another significant issue is the formation of acid due to the presence of moisture and metal particles. As reported by the Air Conditioning Contractors of America (ACCA), the presence of acid can lead to corrosion within the compressor and other critical components, degrading their functionality and leading to premature failures. Moreover, failure to address a faulty filter drier core often results in system inefficiencies, forcing technicians to respond to service calls more frequently, thereby increasing maintenance costs. Regular monitoring and timely replacement of the filter drier core are essential to avoid these issues, ensuring optimal HVAC system performance and longevity.

The bar chart above illustrates the common issues associated with malfunctioning filter drier cores and their respective impact levels on HVAC efficiency. As evident, clogged cores are the most frequent issue affecting system performance, followed by moisture contamination and insufficient cooling capabilities.

Proper maintenance and timely replacement of filter drier cores are critical to ensuring the efficiency and longevity of HVAC systems.

Filter driers serve as key components in refrigeration and air conditioning systems, responsible for removing moisture and debris from the refrigerant lines. According to the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), the presence of contaminants can lead to significant system failures, resulting in costly repairs and decreased performance.

It is generally recommended to check the filter drier core during routine HVAC maintenance at least twice a year, especially before the intense summer and winter seasons when the demand for heating and cooling peaks.

When it comes to replacement practices, HVAC technicians should be trained to identify signs of a failing filter drier core, such as reduced airflow, strange noises from the system, or increased energy consumption—data from the U.S. Department of Energy indicates that inefficient driers can increase energy usage by up to 15%. It is important to replace a filter drier core whenever a refrigeration system is open for service, such as during component replacements or repairs, to prevent the introduction of moisture into the system.

Regular monitoring and adherence to these maintenance practices will not only enhance system efficiency but also extend the lifespan of HVAC equipment, ultimately resulting in lower operational costs.