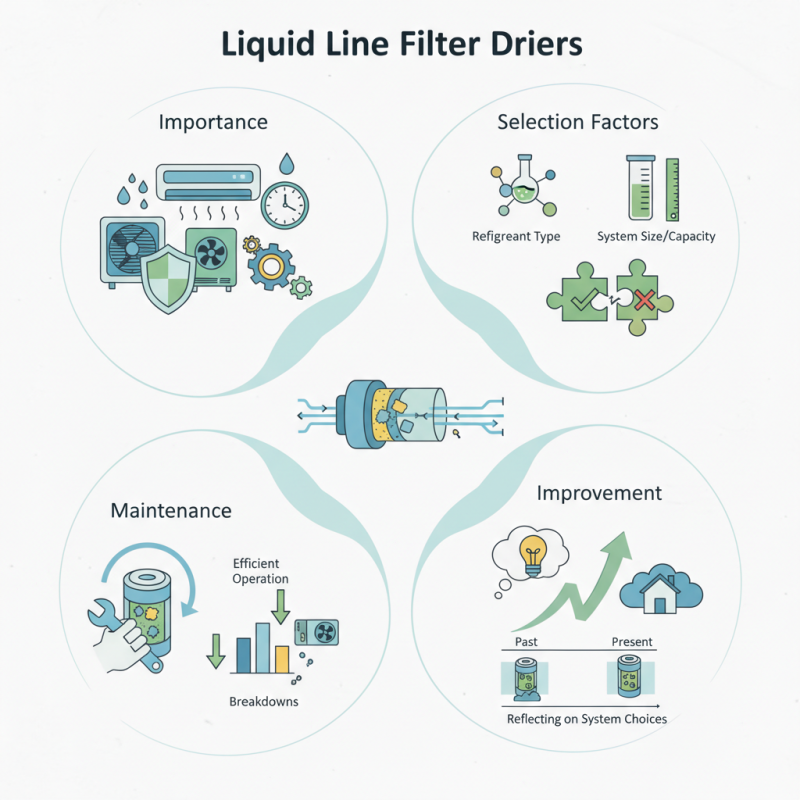

Choosing the right Liquid Line Filter Drier for your HVAC system is crucial. An appropriate filter drier cleans the refrigerant, protecting components from moisture and debris. This helps maintain efficiency and prolongs the lifespan of your system.

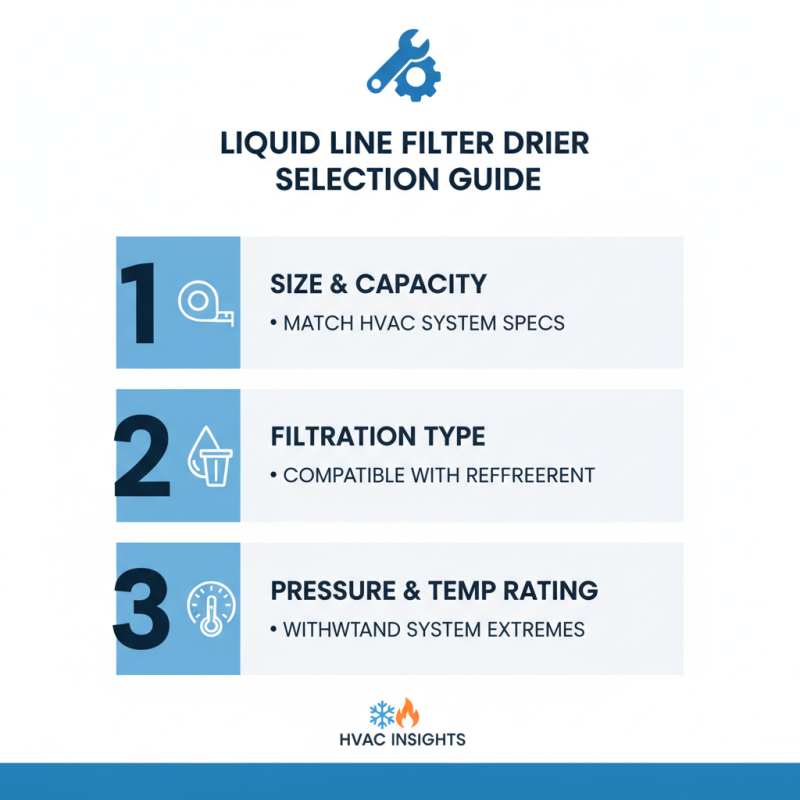

When selecting a Liquid Line Filter Drier, consider the refrigerant type and system size. Different systems require specific filtration capacities. It's also essential to look at compatibility features. Mismatched components can lead to failure and costly repairs.

Many overlook the importance of regular maintenance for the filter drier. This can result in reduced efficiency and unexpected breakdowns. Reflecting on past choices may help in making better selections this time. Awareness of your system's needs is key to improvement and longevity.

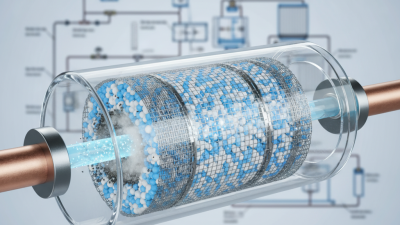

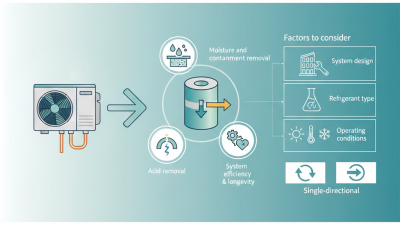

Liquid line filter driers play a crucial role in HVAC systems. They ensure the efficiency and longevity of the system. These components remove moisture and debris from the refrigerant. If moisture enters the system, it can lead to severe damage. The filter drier captures contaminants, preventing them from causing blockages or corrosion.

Choosing the right filter drier can be tricky. Consider factors like refrigerant type and system size. The wrong choice might lead to poor performance or even failures. Some units may not handle high moisture levels effectively. It's essential to assess the specifications carefully. A filter drier should match your system's needs.

Installation is another critical aspect. Even a well-chosen filter drier might underperform if installed incorrectly. Ensure it is placed in a location that allows for easy access. Regular maintenance checks are necessary. Driers can become saturated over time. If neglected, they won't filter effectively. That can shorten the lifespan of your HVAC system.

When selecting the right liquid line filter drier, several key specifications must be considered. The size and capacity of the filter drier play a significant role in its effectiveness. A filter drier that is too small may not adequately remove contaminants. Conversely, one that is too large could lead to inefficiency. It's essential to match the filter drier size with your HVAC system’s specifications for optimal performance.

Filtering efficiency is another crucial factor. Look for specifications that indicate how well the drier can capture moisture and debris. Some models are rated for specific micron sizes. A lower micron rating often means better filtration. However, this might lead to a higher pressure drop. Evaluating this trade-off is vital for your system’s performance.

Compatibility with refrigerants is also important. Not all filter driers suit every type of refrigerant. Check specifications to ensure compatibility. Using an incompatible unit can lead to system damage. Understanding these specifications is fundamental to making an informed choice. Sometimes, even after thorough research, mistakes happen. Always assess the chosen filter drier’s performance after installation. This step can help identify areas needing improvement.

When selecting a liquid line filter drier for your HVAC system, understanding the types available is crucial. There are mainly three types: missile, inline, and combination filter driers. Each type handles moisture differently. A recent industry report highlights that moisture can cause up to 80% of HVAC system failures. This statistic underscores the importance of choosing the right filter drier.

Missile filter driers offer a compact size, which is ideal for small spaces. Inline filter driers provide easier installation and maintenance. Research shows that combination units can offer the best of both worlds. They encapsulate desiccant and filter capabilities. However, compatibility with the existing system is vital. Incompatibility can lead to reduced efficiency and performance issues.

It’s necessary to consider factors such as refrigerant type and system capacity. Some users overlook these aspects, resulting in costly mistakes. Additionally, not all filter driers can handle high humidity. This can be a major flaw in areas prone to moisture. Assessing the operational environment is key for optimal performance.

When selecting a liquid line filter drier for your HVAC system, consider the environmental factors that can impact its performance. Humidity levels, temperature variations, and the presence of pollutants can all play a role in your choice. In high-humidity areas, moisture control becomes crucial for efficient operation. Excess moisture can lead to ice formation or corrosion, affecting system reliability.

Tips: Think about your climate. If you live in a coastal area, salt air can corrode metal parts quickly. Choose a filter drier that offers appropriate materials to withstand corrosive environments.

In arid regions, dust and particulates may pose a risk. Opt for a filter drier designed to handle these contaminants effectively. It is vital to assess your specific conditions and adjust your selection accordingly.

Tips: Monitor your HVAC system regularly. Check the filter drier’s location and accessibility. Regular inspection helps prevent premature failure. Remember, environmental factors can change over time. Stay vigilant and ready to adapt your choice.

Installing and maintaining a liquid line filter drier is crucial for your HVAC system's efficiency. Begin by ensuring the filter drier is compatible with your refrigerant type and system size. Check the specifications closely before making a purchase. Pay attention to the flow direction marked on the filter. Installing it backward can cause significant problems. Use the right tools and protective gear for the installation.

Routine maintenance is essential for the longevity of the filter drier. Regularly inspect it for signs of blockage or damage. A blocked filter can lead to increased pressure in the system. This may reduce cooling efficiency or cause system failure. If you notice any unusual noises, don't ignore them. They may signal a deeper issue with your HVAC system. It's also advisable to replace the filter drier during each major service to ensure optimal performance.

Remember to document the installation and maintenance dates. This can help track the filter's lifespan and notify you when it's time for a change. Cleanliness is vital in the HVAC world. Ensure no debris enters the system during installation. Some people may overlook this step, but it’s critical for maintaining efficiency. Regular checks and a proactive approach can prevent more significant issues down the line.