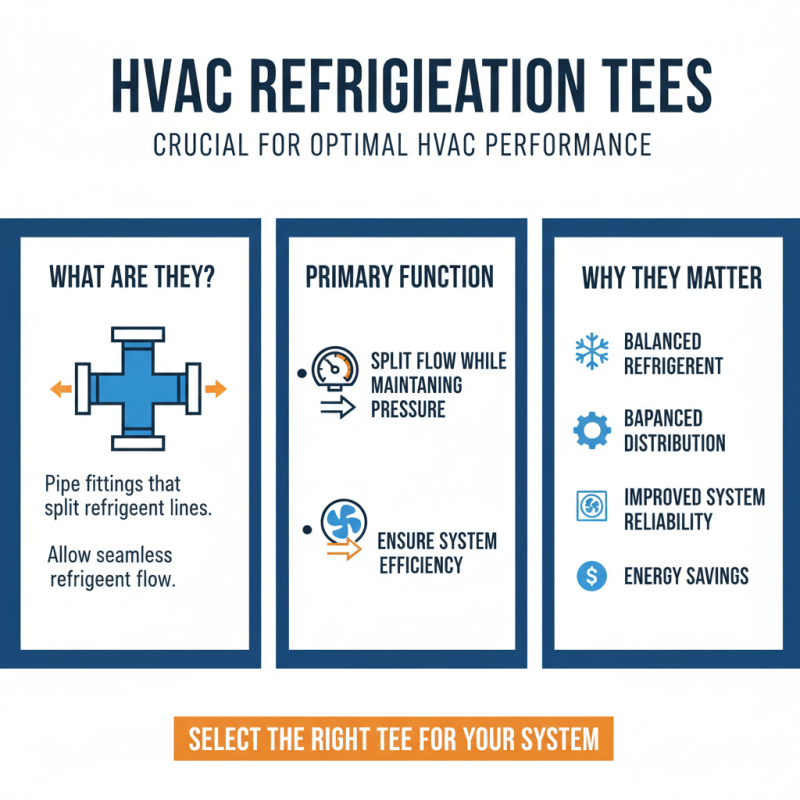

Choosing the right refrigeration tee for your HVAC system is crucial for efficiency and performance. A well-selected refrigeration tee can significantly reduce energy costs. According to the Air Conditioning, Heating, and Refrigeration Institute (AHRI), improper fittings can lead to a 10-15% decrease in system efficiency.

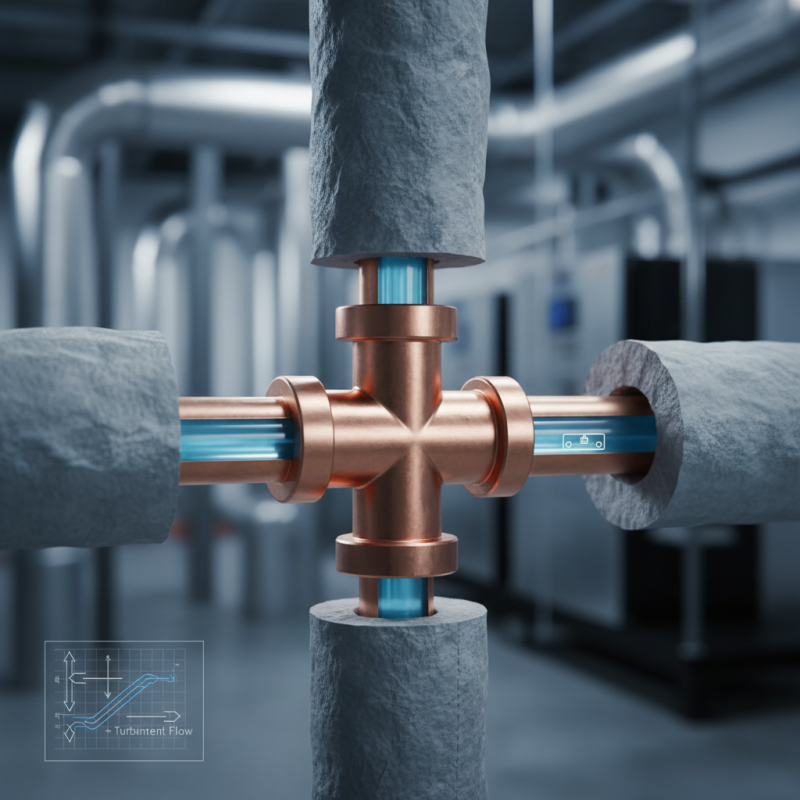

The refrigeration tee acts as a junction for refrigerant flow. A poorly designed or mismatched tee can create turbulence, which damages the system. Choosing the right size and material is vital. The HVAC industry recommends options made from copper or high-quality plastics for durability. Yet, many overlook these details in their decision process.

Errors in selection can lead to costly repairs and inefficiencies. It's essential to evaluate the specifications carefully. Reflect on previous choices. Ask if you prioritized cost over quality. Your decision impacts the entire HVAC system’s performance and longevity. This guide will help navigate those choices effectively.

Refrigeration tees play a crucial role in HVAC systems. They are the junctions that allow refrigerant to flow seamlessly. Understanding their function helps in selecting the right type for your system. A refrigeration tee splits refrigerant lines while maintaining pressure and flow. This balance is vital for efficiency.

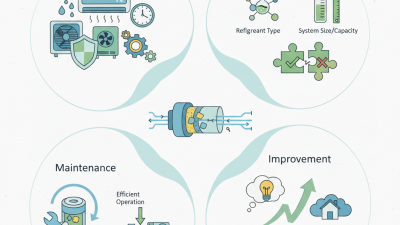

When choosing a refrigeration tee, material and size matter. Copper and PVC are common materials. Each has its advantages. Copper is durable, while PVC is lightweight. Consider the refrigerant type as well. Not all refrigeration tees are compatible with every chemical. A mismatch can lead to leaks or failures.

Installation is another area where mistakes happen. Proper alignment is necessary for optimal performance. Misalignments can cause blockages. These issues often go unnoticed during initial setup. Regular checks can help catch these errors early. Remember, a small oversight can lead to larger problems down the line.

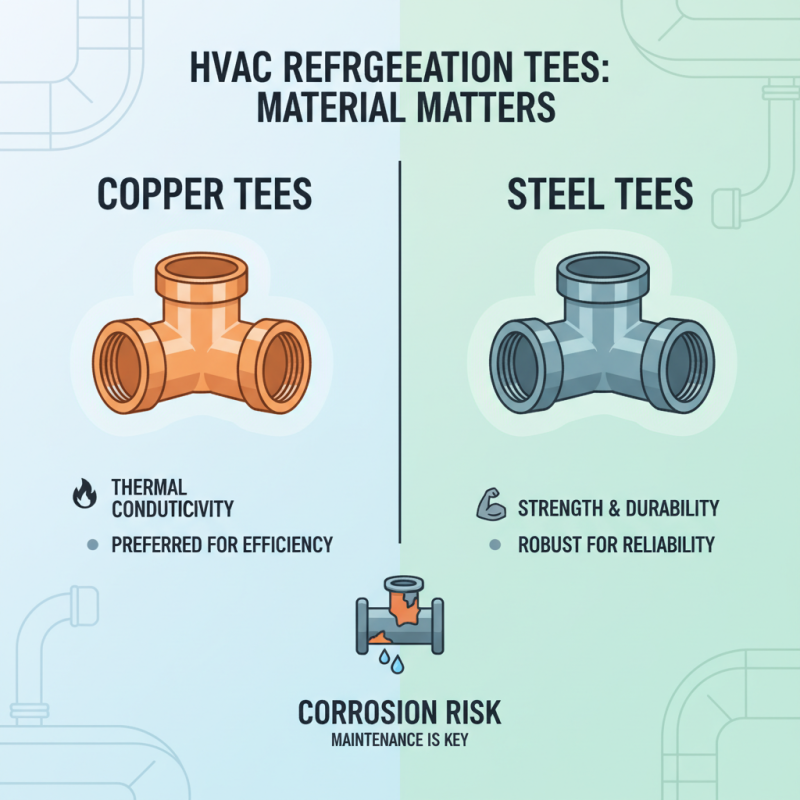

Choosing the right refrigeration tee for your HVAC system is essential for efficiency and reliability. One crucial factor is the material of the tee. Common materials include copper and steel. According to industry reports, copper is favored for its thermal conductivity, while steel is often chosen for its strength and durability. However, both materials can be susceptible to corrosion if not maintained properly.

Another aspect to consider is the size and compatibility of the refrigeration tee. Proper sizing ensures optimal flow and reduces the risk of system strain. A mismatch can lead to inefficiencies. Research indicates that nearly 30% of HVAC failures stem from improper component selection. Evaluate the specifications of your system, and keep in mind the average operating pressure and temperature requirements.

Don’t overlook the installation considerations. A poorly installed refrigeration tee can create leaks, reducing system performance. It’s important to follow best practices during installation. Not all technicians prioritize this. Regular inspections and audits can help identify issues before they escalate. Failure to do so can lead to costly repairs and downtime. Choosing wisely now can save future headaches.

When exploring refrigeration tees, it's essential to understand their types. The most common types include straight tees, angular tees, and reducing tees. Straight tees connect three pipes of the same diameter. They work well in many applications. Angular tees, on the other hand, are used when a change in direction is necessary. They help maintain the flow in a specific direction.

Reducing tees serve a unique purpose. They connect pipes of different sizes. This type can be tricky. Choosing the wrong size can cause pressure losses. Understanding the flow requirements is crucial. It's recommended to evaluate each option carefully. Consider the specific need in your HVAC system. Sometimes, the easiest choice is not the best one.

Installing the wrong type of tee can lead to inefficiencies. This could mean higher energy costs. While it may seem insignificant, a small error can have lasting effects. Reflect on the long-term implications of your choice. An informed decision is vital for maintaining system efficiency and performance.

| Type of Refrigeration Tee | Material | Applications | Pressure Rating (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Standard Refrigeration Tee | Copper | Residential HVAC Systems | 300 | -40 to 200 |

| Welded Refrigeration Tee | Steel | Industrial Refrigeration | 700 | -60 to 250 |

| Soldered Refrigeration Tee | Brass | HVAC Chiller Systems | 400 | -20 to 180 |

| Push-Fit Refrigeration Tee | Plastic | Ductless Mini-Split Systems | 150 | 0 to 120 |

When selecting refrigeration tees for HVAC systems, material choice is critical. Common materials include copper, brass, and stainless steel. Each has unique properties that make it suitable for different applications. Copper is favored for its high thermal conductivity. It’s often the go-to choice for residential systems. Brass offers good resistance to corrosion but may not be ideal for all refrigerants.

Stainless steel, while more expensive, provides excellent durability and resistance to harsh environments. In locations with varying temperatures, this could prevent failures. However, many overlook the importance of compatibility. Mixing incompatible materials can lead to leaks or system failures.

Another aspect to consider is local climate. In humid areas, corrosion can be a major issue. Using materials with protective coatings might be necessary, but that adds complexity. Some HVAC professionals might find these nuances challenging. It requires ongoing evaluation and adjustment. Understanding the dynamic relationship between material properties and application needs is essential for successful system performance.

Choosing the right refrigeration tee is crucial for an efficient HVAC system. Installation plays a significant role in its performance. Proper sealing is vital. Any gaps can lead to refrigerant leaks. This can decrease system efficiency and increase energy costs.

Ensure the refrigeration tee fits snugly in the system. If it's too tight, it can cause stress on the joints. Too loose? Expect vibrations and noise. Always check the manufacturer's guidelines for installation. They often include details about the specific torque settings.

Testing for leaks after installation is essential. Use a leak detector or a soapy water solution. If bubbles form, you've got a problem. Take a moment to reassess your work. Rushed installations lead to regrets. Double-check everything before finalizing. Remember, perfect installations come from experience and oversight. Strive for that, and the system performance will hopefully reflect your efforts.