Choosing and maintaining your Heat Pump Filter Drier is crucial for optimal performance. A well-functioning filter drier contributes significantly to the efficiency of heating and cooling systems. According to the Department of Energy, up to 30% of energy consumption in buildings can be attributed to HVAC systems. This highlights the importance of maintaining components like filter driers to avoid energy loss.

Regular maintenance of your Heat Pump Filter Drier not only enhances efficiency but also extends the lifespan of your heat pump system. Studies show that neglecting this component can lead to costly repairs over time. Filtering impurities and moisture is essential; otherwise, the system can suffer from failures or reduced performance. A clean filter drier can improve overall airflow and reduce energy consumption.

However, many users overlook the importance of proper selection and regular checks. Considering various factors, such as refrigerant type and system capacity, is vital. This decision-making process can be overwhelming. It often requires a balance of professional advice and personal judgement. Remember, a heat pump system's effectiveness is directly related to the quality of its filter drier.

Heat pump filter driers play a crucial role in HVAC systems. They filter particles and moisture from refrigerants. This process helps protect the compressor and other components. A clean system runs efficiently and lasts longer. Clogged filters can lead to serious issues. To maximize efficiency, regular maintenance is essential.

Choosing the right filter drier is vital. Sizes and capacities vary significantly. Consider the specific needs of your HVAC system. What works for one system might not work for another. Installation mistakes can lead to unexpected failures. It's essential to ensure proper fit and compatibility.

Regularly inspecting the filter drier is necessary. Check for any signs of wear or blockage. Ignoring these details can result in higher energy bills. Some homeowners neglect this maintenance step. This oversight can cause long-term damage. Keeping a schedule for checks can help maintain performance.

When selecting a heat pump filter drier, compatibility is key. Ensure it matches your heat pump’s specifications. Size matters, too. An oversized or undersized filter can lead to inefficient performance. Check the flow rate and pressure ratings. These details must fit your system for optimal function.

Another important factor is the type of refrigerant used in your system. Different refrigerants require specific driers to operate effectively. Ignoring this can cause problems down the line. Think about the environment, too. Some materials are better suited for certain conditions.

Regular maintenance keeps your filter drier functioning well. Replace it as recommended by the system's guidelines. Neglecting this can lead to increased wear on your heat pump. Monitoring your performance will help you catch issues early. Sometimes, you might skip regular checks, but that can prove costly. Being proactive can save you from future headaches.

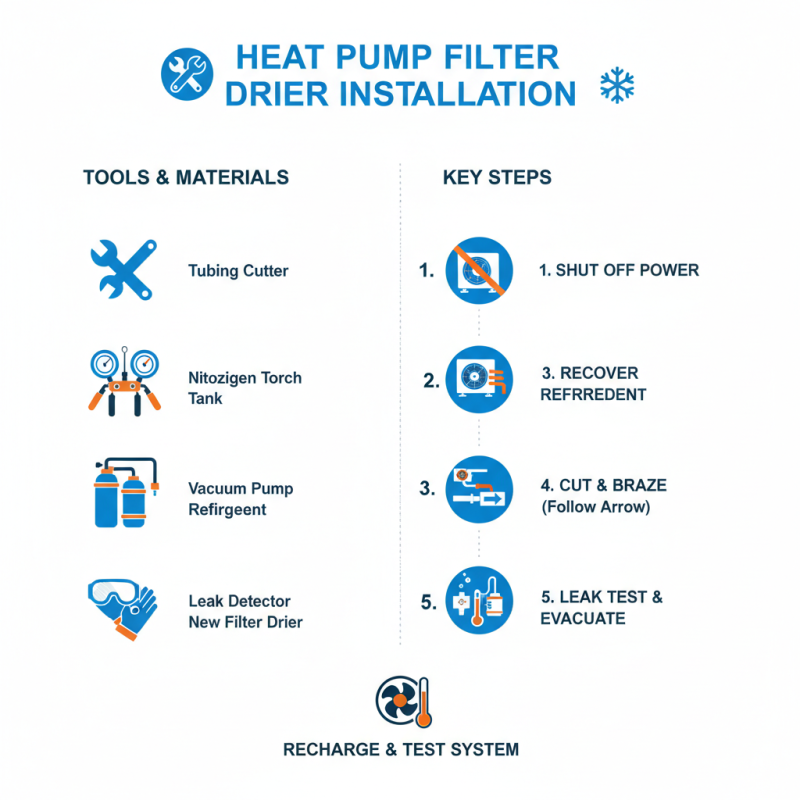

Installing a heat pump filter drier can feel daunting. However, following a few straightforward steps can make the process easier. Start by ensuring the system is off. Safety is always the priority. Next, locate the filter drier in your system. It usually sits between the evaporator and compressor. If it’s not where you expect, double-check the service manual for your specific setup.

Begin by disconnecting the old filter drier. Use appropriate tools to cut the refrigerant lines carefully. Make sure to collect any leaking refrigerant properly. After the old unit is out, measure the line diameters for the new drier. It should match perfectly. When you install the new filter drier, ensure the flow direction arrows are aligned correctly. This small detail is essential for optimal performance. Don’t rush this part; a mistake can lead to inadequate cooling or heating.

After connecting everything, check for leaks. Use a soap solution for this test. Look for bubbling that indicates leaks before you turn the system back on. If you see bubbles, there’s a problem. Tighten connections and test again. Sometimes, the filter drier can be tricky to install correctly. Take your time, and don’t hesitate to review instructions if necessary. Your diligence can greatly affect the system's efficiency and lifespan.

Maintaining your heat pump filter drier is vital for its longevity. Regular checks can prevent costly repairs. Start by inspecting the filter drier every few months. Look for signs of wear or leaks. A small crack can lead to significant issues down the road. If you notice discoloration or dirt buildup, it may be time for a replacement.

Cleaning the drier is essential. Use a soft cloth to remove surface debris. Avoid harsh chemicals that could damage the unit. Pay attention to the filter. If it’s blocked, airflow decreases, impacting efficiency. Change the filter as per the manufacturer’s guidelines. Don’t forget the importance of the surrounding area. Keep it clear of dust and obstructions. Sometimes, we overlook these details, leading to problems later.

Even with routine maintenance, things can go wrong. You might find that the drier fails unexpectedly. Regular checks can help catch issues early. Reflect on your maintenance habits. Are you being diligent? Investing time now will ensure the filter drier serves you well for years. Small efforts in upkeep make a big difference.

When maintaining your heat pump, pay attention to your filter drier. Signs indicate it may need replacement. Common indicators include an unusual increase in energy bills. This often points to inefficiency, possibly caused by a clogged filter drier. According to a recent industry report, 30% of energy loss in HVAC systems results from dirty components.

Another red flag is ice buildup on the evaporator coils. This issue can happen when the filter drier is saturated. The moisture it absorbs can freeze, leading to further complications. Industry professionals suggest checking the filter drier annually, especially in high humidity areas. Regular inspection can prevent costly repairs down the line.

If your system exhibits fluctuating temperatures, it’s another sign. Inconsistent cooling may indicate that the filter drier is struggling. Data shows that a poorly functioning filter can reduce heat pump efficiency by up to 15%. Noticing these signs early can save money and extend the life of your system. Keep a close eye on performance; it will pay off.