In the HVAC industry, the role of the Aluminum Filter Drier is often overlooked. However, its importance cannot be overstated. John Smith, an expert in refrigerant systems, once stated, “The Aluminum Filter Drier is essential for protecting your system from moisture and contaminants.” This highlights the critical nature of this component.

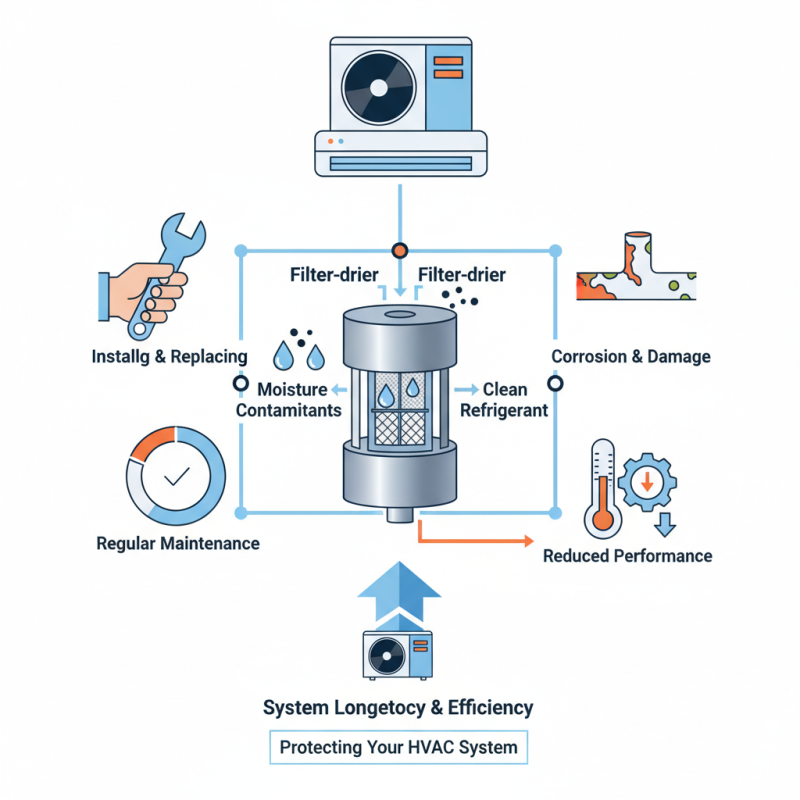

Aluminum Filter Driers serve a vital function. They remove moisture and debris from refrigerants. This helps ensure the longevity and efficiency of your HVAC system. Without them, issues like corrosion and reduced performance can arise. It's concerning how many people underestimate these devices.

Moreover, the design of Aluminum Filter Driers allows them to operate efficiently in various conditions. Yet, they are not infallible. Over time, they can become saturated and ineffective. Regular maintenance and replacement are necessary to keep your system running smoothly. Ensuring your Aluminum Filter Drier is in good condition is crucial for overall system health.

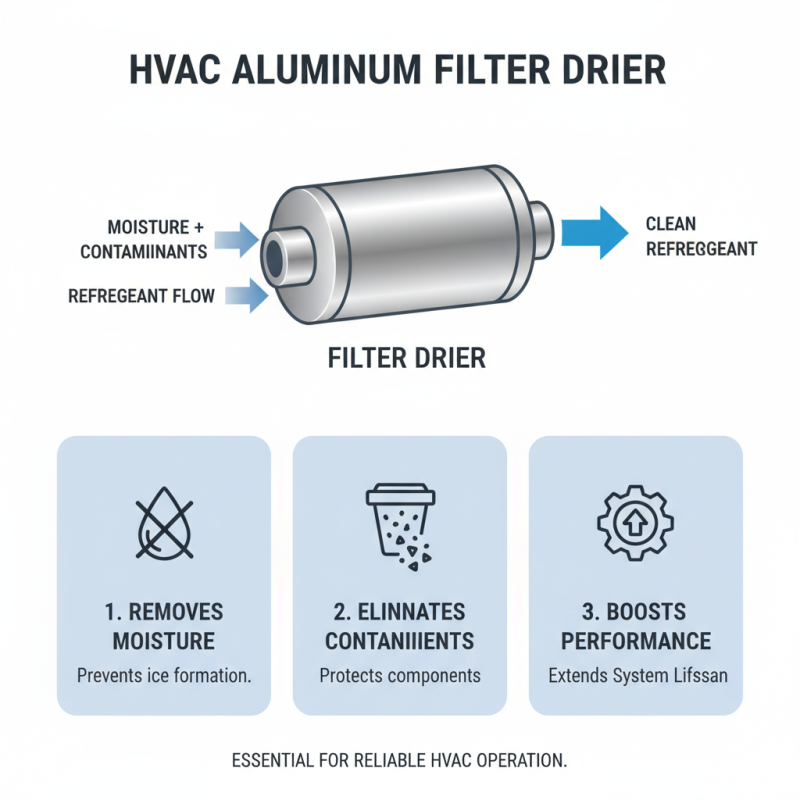

An aluminum filter drier plays a vital role in refrigeration and air conditioning systems. It serves as a key component that removes moisture and contaminants from refrigerants. Moisture can cause significant damage to compressors and reduce system efficiency. In fact, studies show that water and impurities can decrease efficiency by up to 20%. Therefore, a filter drier is essential for preserving system longevity.

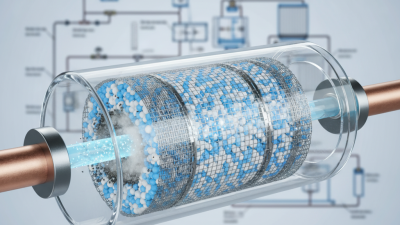

These devices are typically filled with desiccant materials that absorb moisture. As refrigerant flows through the filter drier, contaminants are trapped, ensuring a clean and dry system. The construction of aluminum makes these filter driers lightweight and resistant to corrosion. Additionally, they often have sight glasses, allowing technicians to monitor the condition of the refrigerant visually. This proactive approach helps in identifying issues early.

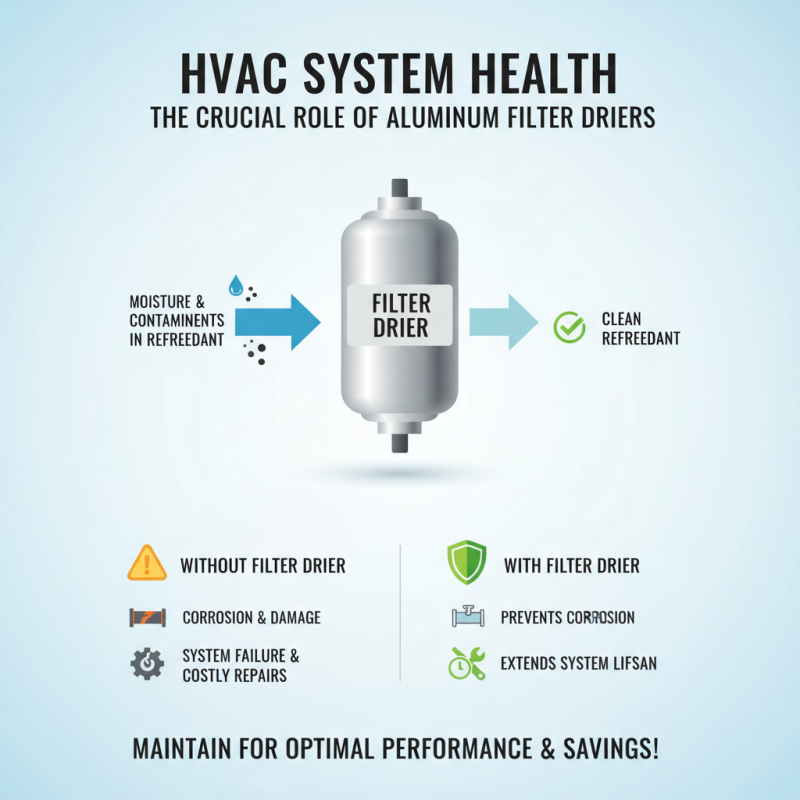

Despite their importance, not all systems are equipped with quality filter driers. Some installations may overlook this aspect, potentially leading to costly repairs. Without proper filtration, systems can experience higher failure rates. Many technicians emphasize performing routine checks on filter driers. Regular maintenance is crucial for optimal performance, yet many users overlook it, compromising system integrity.

Aluminum filter driers are essential components in refrigeration and air conditioning systems. Their primary purpose is to remove moisture and contaminants from refrigerants. The effectiveness of an aluminum filter drier relies heavily on its composition and design. Typically, these filter driers consist of aluminum casings, which offer durability and resistance to corrosion.

The design of aluminum filter driers often includes desiccant materials that absorb moisture. This ensures the refrigerant remains clean and functional. Some filter driers also feature a built-in filtration system. This system captures solid particles, preventing them from circulating within the system.

However, the design may vary, and sometimes manufacturers overlook crucial elements, leading to issues like reduced efficiency.

It's important to note that not all aluminum filter driers are created equal. Some designs may be prone to clogging, which could impact performance. Regular checks are vital to identify potential problems before they escalate. Users should reflect on their choices and ensure they select filter driers that minimize risk and maximize efficiency. Exploring various options can also reveal better solutions for specific needs.

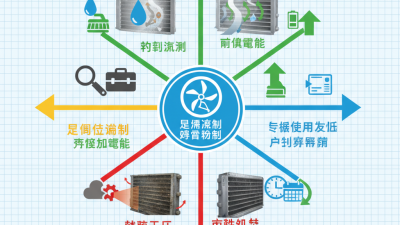

Aluminum filter driers play a crucial role in HVAC systems. They are designed to remove moisture and contaminants from refrigerants. Moisture can cause corrosion and system failures. Thus, the filter drier helps maintain system efficiency and longevity.

In an HVAC setup, these driers contain desiccant materials that absorb moisture. They trap particles like dust and debris, preventing them from circulating within the system. Regular maintenance can reveal if the filter drier is functioning well. However, some might overlook this component until issues arise. Neglecting a clogged filter drier could lead to costly repairs later.

The importance of inspecting aluminum filter driers cannot be overstated. They can impact refrigerant flow and overall performance. Yet, many users may not fully understand their function. Regular checks can prevent unexpected breakdowns and improve energy efficiency. Keeping these components clean keeps air quality optimal too.

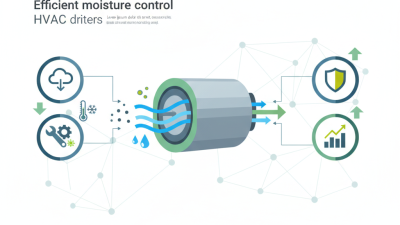

An aluminum filter drier is essential in HVAC systems. It serves a crucial role in removing moisture and contaminants from refrigerants. This not only enhances system performance but also prolongs its lifespan. By eliminating moisture, the filter drier prevents ice formation. This is vital for keeping the compressor and other components functioning smoothly.

Efficiency is a key concern for any HVAC system. When the system operates without impurities, it can maintain optimal cooling levels. A clean refrigerant leads to better thermal exchange and reduced energy consumption. However, dirty or clogged filter driers can lead to complications. They can cause pressure drops, reducing the system's overall efficiency.

Regular checks and maintenance are often overlooked. This can result in decreased performance over time. It's important to remember that neglecting the filter drier can lead to costly repairs. Therefore, understanding its importance is vital for anyone involved in HVAC maintenance. Keeping an eye on these components ensures a longer lifespan for the entire system.

Aluminum filter driers are essential in HVAC systems. They remove moisture and contaminants from refrigerants. Without them, corrosion can occur. This can lead to system failure and costly repairs. Therefore, maintaining these components is crucial for overall system health.

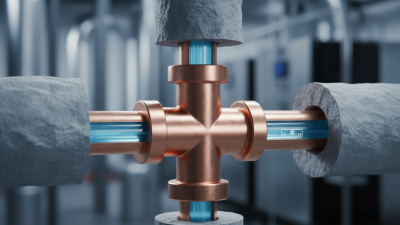

Common issues with aluminum filter driers include clogging and improper installation. Clogging can restrict airflow and reduce efficiency. Inspecting and replacing driers regularly helps prevent this. Improper installation may cause leaks. Ensure all connections are tight and secure. Routine checks can spot issues early, saving time and money.

Maintenance tips for filter driers include regular inspections. Look for any physical signs of wear, such as dents or cracks. Documenting the age of the drier can help assess replacement needs. Keep an eye on system performance. If you notice unusual noises, consider checking the drier. These simple steps can lead to a more reliable system.