Refrigeration evaporator coils play a critical role in cooling systems. Their efficiency directly impacts energy consumption and operational costs. According to a recent study by the U.S. Department of Energy, poorly maintained coils can increase energy usage by up to 30%. This statistic highlights the importance of selecting the best refrigeration evaporator coils for various applications.

In the commercial sector, refrigeration is vital for food preservation. An article from Food Industry News noted that efficient coils can extend food shelf life significantly, reducing waste. Proper coil selection improves not only cooling performance but also enhances the sustainability of operations. However, many consumers often overlook these aspects when making their choices.

Purchasing refrigeration evaporator coils can be overwhelming. The market is filled with options that vary in efficiency, size, and price. Understanding the technical specifications and real-world applications of these coils is crucial. Choices should reflect specific needs and long-term benefits. Failing to do so can lead to unexpected costs and inefficiencies down the line.

Refrigeration evaporator coils play a vital role in cooling systems. These coils absorb heat from the air or liquid, turning it into vapor. This process is essential for maintaining low temperatures in refrigeration units. Without effective evaporator coils, your refrigeration system may struggle to maintain the desired temperature.

Tips: Regular maintenance is crucial. Check for any signs of frost buildup. Ensure the coils are clean and free from debris. This can improve efficiency. Consider the sizing of the coils. Oversized or undersized coils can reduce performance and increase energy costs.

Understanding the importance of evaporator coils is key. They directly impact energy consumption and humidity control. Neglecting their care can lead to higher energy bills. It may also shorten the lifespan of your refrigeration unit.

The investment in quality coils is worthwhile. A well-maintained system can offer better efficiency over time, reducing operational costs significantly.

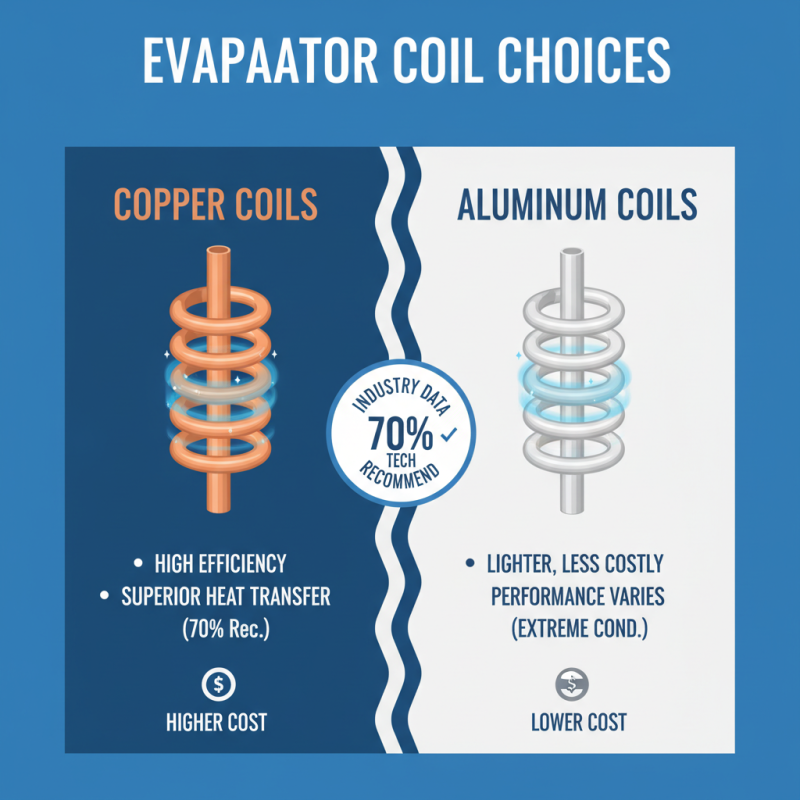

When choosing evaporator coils, several key features demand attention. The material of the coils plays a crucial role. Copper coils are highly efficient but can be more expensive. Aluminum coils are lighter and less costly, yet they may not perform as well in extreme conditions. According to industry data, 70% of technicians recommend copper for superior heat transfer.

Another important factor is the coil's thickness. Standard thicknesses range from 0.020 to 0.025 inches. Thicker coils often provide better heat exchange. However, they can also make installation challenging. In fact, many installers face difficulties fitting thicker coils into tight spaces. A recent survey highlighted that 40% of HVAC professionals encounter installation issues due to coil size.

Moreover, the configuration of the coils can affect overall performance. Coils with a larger surface area are generally more effective. They allow for better airflow and cooling. However, larger coils may need more maintenance. Some users find themselves neglecting upkeep, leading to reduced efficiency over time. Balancing performance and maintenance is crucial when selecting the right evaporator coils.

In 2026, the refrigeration evaporator coil market shows significant innovation and competition. This sector is crucial for efficient cooling systems across various industries, including food preservation. According to industry reports, the demand for energy-efficient evaporator coils has increased by 15% over the past two years. Brands focusing on eco-friendly materials are gaining traction. This shift reflects a larger trend towards sustainability in refrigeration.

A variety of materials are used in high-performance coils. Copper remains popular for its excellent thermal conductivity. Aluminum is often preferred for its lightweight properties. Some manufacturers are exploring advanced polymer composites. These new materials can be more cost-effective but may also have longevity issues. Evaluating the long-term performance of different materials is essential for buyers.

The top brands have invested in R&D, enhancing efficiency ratings. However, discrepancies in performance metrics remain a concern. Some coils underperform in specific temperature ranges. Potential buyers should scrutinize product specifications. Not all high-efficiency models live up to their claims. Researching consumer reviews alongside industry data can help in making informed choices.

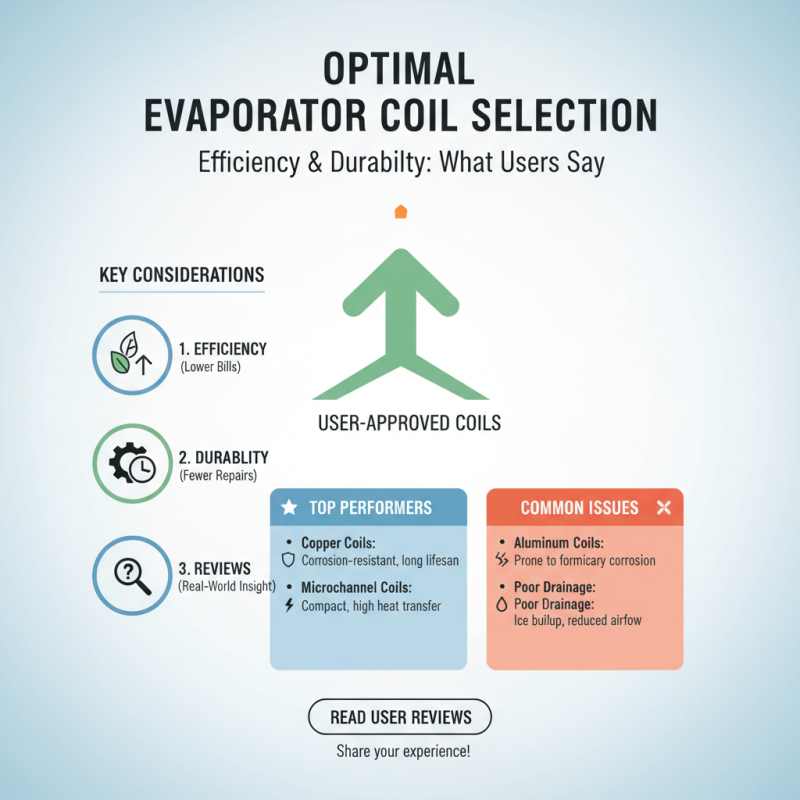

Choosing the right evaporator coil is crucial for efficient refrigeration. Many users often share their experiences online. These reviews provide insight into various models and their performances. Some coils stand out for their durability, while others struggle under similar conditions.

User feedback highlights common issues like noise and inefficiency. Some coils reportedly produce excessive vibrations, which can be annoying. Others, despite high expectations, may not cool as effectively as claimed. These issues remind potential buyers to research thoroughly before committing.

Many customers appreciate coils that balance performance and cost. Price-sensitive users often feel torn between saving money and investing in quality. Inconsistent reviews sometimes lead to confusion. Evaluating multiple sources and user experiences is essential for making an informed decision.

Proper installation of evaporator coils is crucial for efficient refrigeration. Incorrect installation can lead to reduced performance. Typically, the gap between the coil and the wall should be at least 2 inches. This space allows for proper airflow, which enhances efficiency. According to industry reports, a well-installed evaporator can increase system efficiency by 15%.

Maintenance is equally important. Regular cleaning of evaporator coils can significantly improve cooling capabilities. Dust and debris can accumulate over time, creating insulation. This buildup can lower the system’s efficiency, sometimes by as much as 30%. Technicians recommend inspecting coils every six months. Simple tasks, like vacuuming dust, can prevent costly breakdowns. Neglecting this can lead to refrigerant leaks and further complications.

The environment in which coils operate also plays a role. High humidity can affect coil performance negatively. Monitoring humidity levels is critical. If humidity exceeds 70%, efficiency drops. Regular checks can help maintain optimal performance. Ignoring these factors might lead to unforeseen issues. Planning regular maintenance is vital for long-term efficiency.